Rust is a common enemy, stealthily creeping onto metal surfaces and threatening their structural integrity. It’s more than just a cosmetic issue; rust can significantly weaken metals, leading to costly repairs or replacements. For industrial professionals, car enthusiasts, and even homeowners, understanding rust is crucial to maintaining the longevity and safety of metal structures.

Rust, scientifically known as iron oxide, forms when iron reacts with oxygen in the presence of water or moisture. This chemical reaction results in a flaky, reddish-brown layer that gradually eats away at metal. The process can be accelerated by environmental factors such as humidity, exposure to saltwater, and acidic substances. Knowing how rust forms helps in devising strategies to combat it effectively, ensuring that metal components remain sturdy and reliable.

To tackle rust effectively, one must first grasp its nature. Rust formation is an electrochemical process where iron loses electrons to oxygen, forming iron oxide. This knowledge highlights the importance of cutting off the rust formation cycle, either by removing one of the reactants or by using protective coatings. By understanding this process, individuals can make informed decisions about prevention and treatment methods, saving time and resources.

The Role of Rust Penetrants

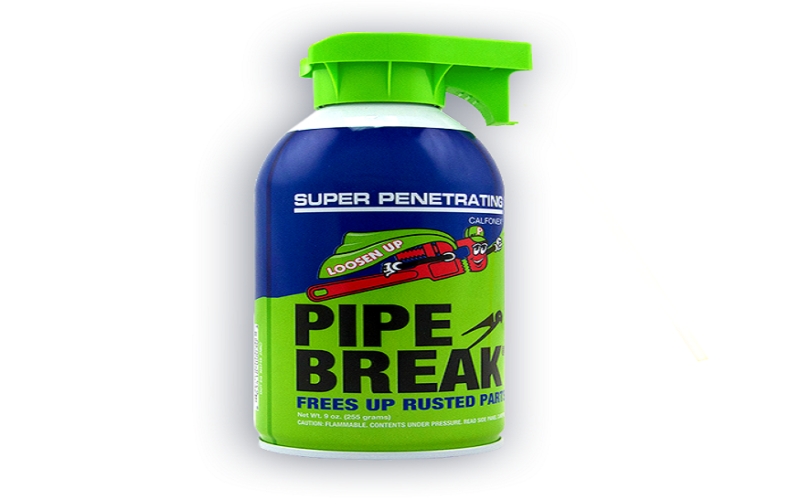

Rust penetrants play a pivotal role in the battle against corrosion. These specialized sprays are designed to penetrate rust layers, breaking them down and loosening seized components. For those dealing with stubborn nuts and bolts or machinery parts, rust penetrants are invaluable tools that can save both time and effort. Understanding the role of these products enhances their effective use and maximizes their benefits.

Penetrating sprays work by seeping into the tiny spaces between rust particles and the underlying metal surface. This action reduces friction and lubricates the parts, allowing for easier movement. Such sprays contain solvents and oils that dissolve rust and provide a protective layer against future corrosion. Recognizing this dual action of rust penetrants highlights their importance in both immediate repairs and long-term maintenance strategies.

Using the best rust penetrant requires choosing a product tailored to specific needs. Factors such as the type of metal, extent of rust damage, and environmental conditions should guide the selection process. Some penetrants offer additional benefits like moisture displacement and long-lasting lubrication. By selecting the right product, users can enhance the effectiveness of their rust-fighting efforts, ensuring optimal results.

Choosing the Best Rust Penetrant

With numerous rust penetrants available on the market, selecting the right one can be challenging. Each product has unique properties and formulations designed for specific applications. To make an informed choice, consider factors such as the severity of corrosion, the type of metal, and the operating environment. Evaluating these aspects ensures that the chosen rust penetrant effectively addresses the problem at hand.

Look for penetrants with high solvency power, as they are more effective at breaking down rust and freeing stuck components. Some products are formulated for heavy-duty applications, while others are more suitable for light maintenance tasks. It’s important to match the penetrant to the specific needs of the task, whether it’s loosening a rusty bolt or protecting machinery from future rust damage.

Additionally, consider penetrants that offer multi-functionality, such as those that provide lubrication or moisture protection. These features can add value by extending the lifespan of metal components and reducing maintenance frequency. By choosing a versatile product, users can achieve not only immediate rust removal but also long-term prevention, enhancing the overall efficiency of their maintenance routines.

Applying Rust Penetrating Spray Effectively

Proper application of rust penetrating spray is essential to achieving desired results. Begin by cleaning the area to remove loose debris and surface rust, allowing the spray to penetrate more deeply. Shake the can well before use to ensure an even distribution of active ingredients. Applying the spray generously allows it to seep into small crevices, maximizing its rust-breaking capabilities.

Allow the penetrant to sit for the recommended duration, typically a few minutes to an hour, depending on the severity of rust. This waiting period enables the spray to dissolve rust and lubricate the metal thoroughly. In stubborn cases, reapplication may be necessary to achieve full penetration and release.

After sufficient time, gently tap the metal parts to break the rust bond further, then attempt to move or unscrew them. Patience is key, as forcing movement can cause damage. With careful application and patience, rust penetrating sprays can effectively restore the functionality of rusted components, making them a valuable tool in any toolkit.

Preventing Rust Formation

Prevention is always better than cure when it comes to rust. Implementing preventive measures can save time, money, and effort in the long run. One effective strategy is applying protective coatings to metal surfaces, creating a barrier against moisture and oxygen. These coatings can be paints, primers, or specialized rust inhibitors designed to offer long-lasting protection.

Regular maintenance is another crucial aspect of rust prevention. Inspect metal components frequently for early signs of rust and address them promptly. Removing surface rust before it penetrates deeper can prevent extensive damage. Additionally, storing metal items in dry, well-ventilated areas minimizes exposure to moisture, reducing the risk of rust formation.

Adopting these preventive measures ensures that metal assets remain in excellent condition, enhancing their durability and performance. By integrating rust prevention into routine maintenance practices, individuals can extend the lifespan of their metal equipment and structures, safeguarding their investments effectively.

Your Rust-Free Future Awaits

Understanding rust and how to combat it with rust penetrating sprays is essential for maintaining the integrity of metal components. By grasping the science behind rust, choosing the best rust penetrants, and applying them effectively, individuals can successfully tackle corrosion challenges. Implementing preventive measures further protects metal assets, ensuring their longevity and reliability.

For those seeking to enhance their rust-fighting arsenal, exploring a variety of rust penetrants and protective solutions is a wise step. Consider consulting with experts or joining communities focused on rust prevention to gain valuable insights and tips. By staying informed and proactive, you can safeguard your metal investments and enjoy a rust-free future.