In various industries, prototype injection moldingis accessed for the production of the machine parts. It becomes one of the highly necessary methods to produce the parts to complete your entire project. Usually, business owners use plastic injection molding, which is quite an expensive and long procedure as well.

Because of the rapid growth in the technological field, it is definitely important to take some time and understand the method, which works the best for your project and gives great value for money. In the rapid prototyping production, it is extremely possible to take advantage of the rapid plastic injection molding parts/tools.

Even though the process of the injection molding is similar to series production tooling, it is adapted to certain specifications. Keep reading to know the benefits of the prototype molding technology!

What is the injection prototype molding?

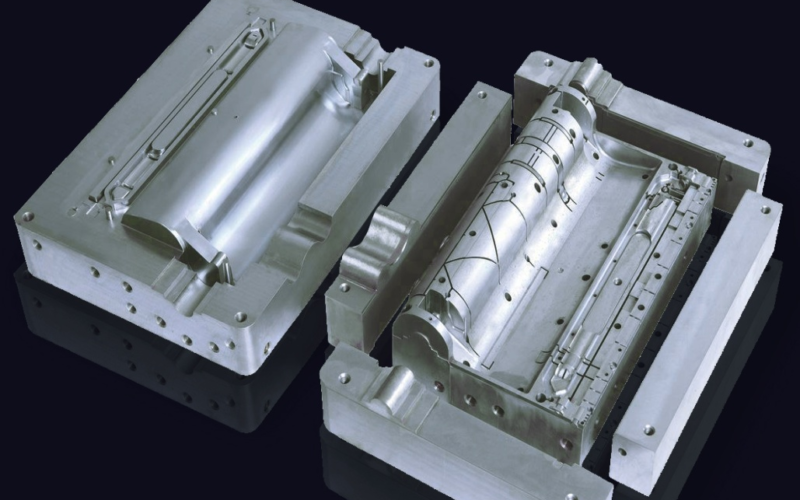

As the name suggests, the prototype molding is designed for the rapid production of the prototypes. It produces the plastic prototypes of up to thousands of parts. This method is specially designed to produce small series, prototypes, and samples instantly and economically. The properties of the injected parts are much similar to the series mold. However, the lifespan of the series mold is low when compared to injected parts. This is where the process of injection molding becomes the first choice of business people. This technology is highly preferred to the silicone mold, where the number of parts is considerable.

Benefits of injection prototype molding

Take a glance at the advantages you get from the prototype injection molding.

Since this process uses soft metal and aluminum alloy to produce prototypes, the concept risk is reduced a lot. This kind of material is much easier forthe machine when compared to metal. Additionally, the mold will not be included in all the first series functionalities. This process makes it easier and simpler to make adjustments as well as modifications to the cavities. It also provides greater flexibility at the prototyping stage and production of the transition series.

Even though plastic injection molding is one of the expensive and costly prototyping technology, your initial investment will be reduced when opting for the prototype mold to deliver your parts. It also permits the production of numerous parts in a short time.

This process accelerates the manufacturing process greatly. Within a short time, your first right material will be products, i.e., usually between two to four weeks. Based on the cavities’ complexity, it is extremely faster than the machine. This is why it is considered as the best solution to increase speed.

This prototype molding is one of the most efficient and economical prototyping solutions because it offers complex shapes, huge choices of materials, precise tolerance, and excellent finishing. With this molding, insert, and over-molding are also possible, and therefore, you can complete your project within a short time.

Apart from these, you can avail of tons of benefits from this prototype molding process, but you need to engage with the right service provider.